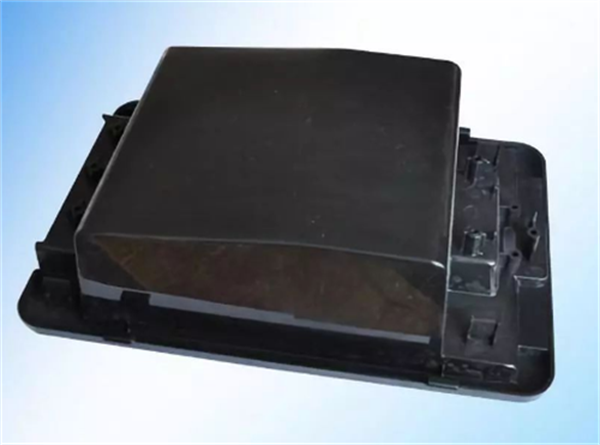

Warpage deformation e bua ka ho sothoa ha sebopeho sa sehlahisoa se entsoeng ka ente le warpage, ho kheloha litlhoko tsa ho nepahala ha sebopeho sa karolo, ke e 'ngoe ea liphoso tse lokelang ho rarolloa ka moralo le tlhahiso ea hlobo.

Ke eng e bakang mathata le mokhoa oa ho ntlafatsaeona?

Sebopeho sa hlobo, thepa ea thermophysical ea thepa ea polasetiki le maemo le litekanyetso tsa mokhoa oa ho bopa kaofela li na le likhato tse fapaneng tsa tšusumetso holim'a warpage le deformation ea sehlahisoa.

1. Litšitiso tsa hlobo

Moralo oa hlobo o etsa qeto ea hore na karolo ea warpage ke efe, 'me ho thata haholo ho hatella tšekamelo ena ka ho fetola maemo a ho bōpa, kahoo tharollo ea ho qetela e tlameha ho qala ho tloha moralo oa hlobo le ntlafatso.

(1) Ho ntlafatsa hlobo e le hore botenya le boleng ba karolo e tšoane haholo.

(2) moralo oa tsamaiso tsidifatso ho etsa hore hlobo cavity mocheso junifomo likarolong tsohle, thickening loketseng ho feta ho thata ho etsa karolo ea manifold, kanale e khōlō phallo, khutsufatsa phallo sebaka, ka hohle kamoo ho ka khonehang ho felisa Phapang ea letsoalo la cavity, phapang ea khatello, phapang ea mocheso.

(3) Sebaka sa phetoho le likhutlo tsa botenya ba karolo e lokela ho ba boreleli ka ho lekaneng 'me e be le ho lokolloa ha hlobo e ntle, joalo ka ho eketsa moeli oa ho lokolloa, ho ntlafatsa ho belisoa ha hlobo, ho fokotsa botenya ba lera le leqhoa ha ho tlatsa hlobo. , ho fokotsa khatello ea kelello ea ka hare le ho boloka ho leka-lekana ha tsamaiso ea ejector.

(4) Ho etsa bonnete ba hore ho na le moea o motle.

(5) Eketsa botenya ba lerako la karolo kapa ho eketsa tataiso ea ho hanyetsa warp, ka ho matlafatsa matlafatso ho matlafatsa khanyetso ea warp ea karolo.

2. Taolo e fosahetseng ea ho sebetsa le maemo a ho bōpa

Ts'ebetsong ea ho bopa ente, polasetiki e qhibilihisitsoeng sethaleng sa ho tlatsa hlobo ka lebaka la tlhophiso ea limolek'hule tsa polymer haufi le tsela ea phallo e le hore polasetiki e ka lehlakoreng la phallo ea sekhahla sa shrinkage ho feta tataiso e otlolohileng ea sekhahla sa shrinkage, 'me ente e bopehile. likarolo tsa warpage deformation (ke hore anisotropy).Ka kakaretso, shrinkage ea junifomo e baka feela liphetoho bophahamong ba karolo ea polasetiki, shrinkage e sa lekanang feela e tla baka deformation ea warpage.

Khatello ea ente, sekhahla le liparamente tse ling tsa mochini oa ente, sethala sa ho tlatsa le ho pholile ha mocheso, khatello, lebelo la tse tharo li kopantsoe hammoho, ts'ebetso ea ente, phapang ea mocheso lipakeng tsa libaka tse fapaneng tse bakoang ke khatello ea mocheso, deformation ea mocheso kapa mocheso. shrinkage e sa lekanyetsoang e bakang motsotsoana, e ka 'na ea etsa hore likarolo tsa polasetiki tsa warpage li fetohe

(1) Fokotsa khatello ea ente le ho khutsufatsa nako ea ho ts'oara ho netefatsa mocheso o lekaneng oa ho qhibiliha ho qoba ntoa ka lebaka la khatello e eketsehileng ea ka hare.

(2) Fokotsa mocheso oa hlobo 'me u eketse nako ea ho pholile ho qoba ho chesa ha karolo nakong ea deformation le ejection deformation.

(3) Fokotsa lebelo la screw le khatello ea mokokotlo ho fokotsa boima ba 'mele ha u ntse u boloka tefiso e fokolang ho fokotsa khatello ea ka hare.

(4) Haeba ho hlokahala, sebopeho se bonolo sa hlobo kapa ho senya ka mor'a ho senya ho ka etsoa bakeng sa likarolo tse atisang ho ba le warpage le deformation.

Ha ho etsoa ente, ho tla ba le mathata a mangata, Xiamen Ruicheng o na le phihlelo ea lilemo tse fetang 20 tšimong ena, e ka u fang tšehetso ea tekheniki le thuso.Na u ka rata ho tseba ho eketsehileng?Ikopanye le rona hona joale!

Nako ea poso: Feb-03-2023