Die casting, e leng ts'ebetso ea tlhahiso e fapaneng haholo, e na le nalane e ruileng ea lekholong la bo19 la lilemo.E qalileng e ntlafalitsoe ho hlahisa mofuta o suthisoang bakeng sa indasteri ea khatiso, die casting e ile ea atolosoa ka potlako lits'ebetsong tse ling ka lebaka la bokhoni ba eona ba ho hlahisa libopeho tse rarahaneng ka ho nepahala ho phahameng le ho pheta-pheta.Ho theosa le mashome a lilemo, tsoelo-pele ea thepa le thekenoloji e ntlafalitse haholo ts'ebetso ea ho lahla, ea e etsa motheo oa tlhahiso ea sejoale-joale bakeng sa liindasteri tse fapaneng, ho kenyeletsoa likoloi, sefofane, lisebelisoa tsa elektroniki le thepa ea bareki.

Mekgwa ya pele ya ho etsa die casting e ne e sebedisa loto le thini e le disebediswa tsa mantlha, tseo hamorao di ileng tsa nkelwa sebaka ke dimetale tse tšoarellang le tse tenyetsehang tse kang aluminium, magnesium le alloy zinki.Lisebelisoa tsena li ne li fana ka thepa e phahameng ea mochini, ho hanyetsa kutu, le litšobotsi tse bobebe, tse etsang hore e be tse loketseng lits'ebetso tse fapaneng tse sebetsang hantle.Kenyelletso ea "high-press die casting" lekholong la bo20 la lilemo e ile ea fetola indasteri, ea lumella tlhahiso ea likarolo tse rarahaneng tse nang le liphetho tse ikhethang tsa bokaholimo le ts'ebetso e fokolang ea morao-rao.

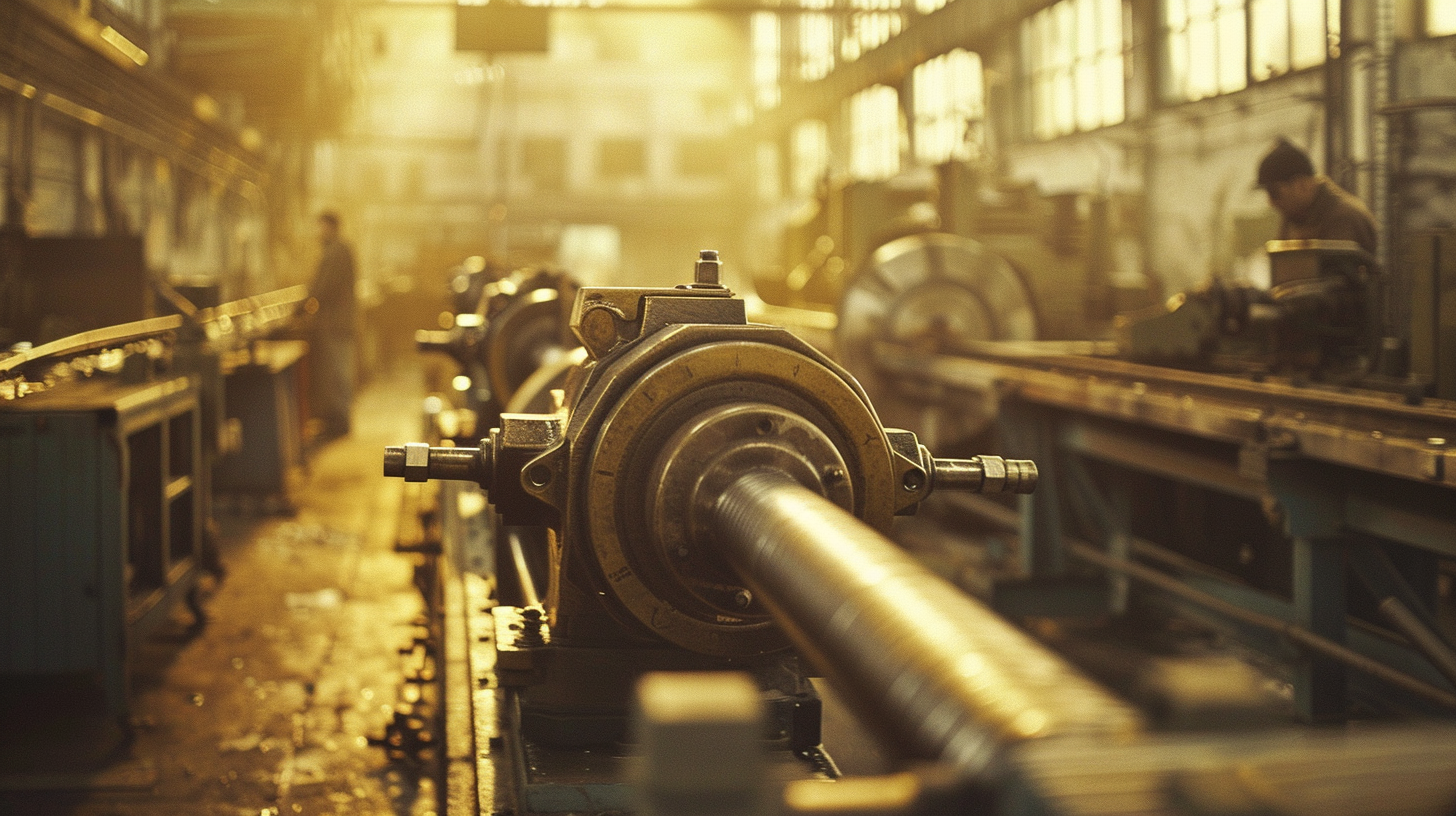

Ho Ruicheng, re sebelisitse matla a theknoloji ea sejoale-joale ea ho lahla lefu ho fa bareki ba rona lihlahisoa tsa boleng bo holimo.Mehaho ea rona ea morao-rao e na le mechini ea morao-rao ea khatello e phahameng ea khatello le litsamaiso tse tsoetseng pele tsa othomathike, tse netefatsang ho nepahala, ho sebetsa hantle, le botsitso morerong o mong le o mong oo re o etsang.

E 'ngoe ea matla a rona a mantlha a ho lahlela lefu ke mokhoa oa rona o felletseng oa taolo ea projeke.Ho tloha mohatong oa pele oa moralo ho isa tlhahiso ea ho qetela, re sebetsa haufi-ufi le bareki ba rona ho utloisisa litlhoko tsa bona tse ikhethileng le ho hlophisa lits'ebetso tsa rona ho fihlela litlhaloso tsa bona hantle.Sehlopha sa rona sa baenjiniere ba nang le boiphihlelo se sebelisa software e tsoetseng pele ea ketsiso ho ntlafatsa meralo ea hlobo le liparamente tsa ho etsa, ho netefatsa phallo e nepahetseng ea thepa le ho tiisa.Mokhoa ona o sebetsang o thusa ho fokotsa mefokolo e kang porosity, shrinkage, le warping, e leng se hlahisang boleng ba boleng bo phahameng, bo tšoarellang.

Ho feta moo, boitseanape ba rona bo fetela ka nģ'ane ho ts'ebetso ea ho lahlela ka boeona.Re fana ka mefuta e mengata ea ts'ebetso ea bobeli, ho kenyelletsa le mochini oa CNC, ho qeta bokaholimo, le kopano, ho fana ka tharollo e felletseng ea ho qetela bakeng sa bareki ba rona.Mekhoa ea rona ea ho laola boleng e tsitsitse, e kenyelletsang tlhahlobo e qaqileng le liteko sethaleng se seng le se seng sa tlhahiso ho netefatsa hore karolo ka 'ngoe e finyella litekanyetso tse phahameng ka ho fetisisa tsa ho nepahala le ts'ebetso.

Boikarabello ba tikoloho ke motheo o mong oa ts'ebetso ea rona Ruicheng.Re ikemiseditse ho etsa ditlwaelo tsa moshwelella tsa tlhahiso, ho kenya tshebetsong mehato ya ho fokotsa tshenyo, ho sebedisa thepa hape, le ho fokotsa tshebediso ya matla.Maiteko a rona a eco-friendly ha a thuse feela ho sireletsa tikoloho empa hape a kenya letsoho ho bolokeng litšenyehelo le lintlafatsong tse sebetsang hantle, tseo re li fetisetsang ho bareki ba rona.

Qetellong, tsoelo-pele ea "die casting" ho tloha qalong ea boemo bo tlaase ho fihlela boemong ba hona joale e le ts'ebetso ea bohlokoa ea tlhahiso e totobatsa tsoelo-pele e kholo ea thepa le theknoloji ho theosa le lilemo.Ho Ruicheng, re phahamisa tsoelo-pele ena ho fana ka lits'ebeletso tse ikhethang tsa ho hlahisa lefu, tse khetholloang ka ho nepahala, boleng le botsitso.Boitlamo ba rona ho boqapi le bokhabane bo tiisa hore re lula re le ka pele ho indasteri, re fa bareki ba rona tharollo e tšepahalang le e sebetsang bakeng sa merero ea bona e thata ka ho fetisisa.

Nako ea poso: Jul-19-2024