-

3D Printing: A Game-Changer in Additive Manufacturing

Stereolithography (SLA) is one of the most popular and widely used 3D printing technologies today. Originating in the early 1980s, SLA has since revolutionized the way we ...Read more -

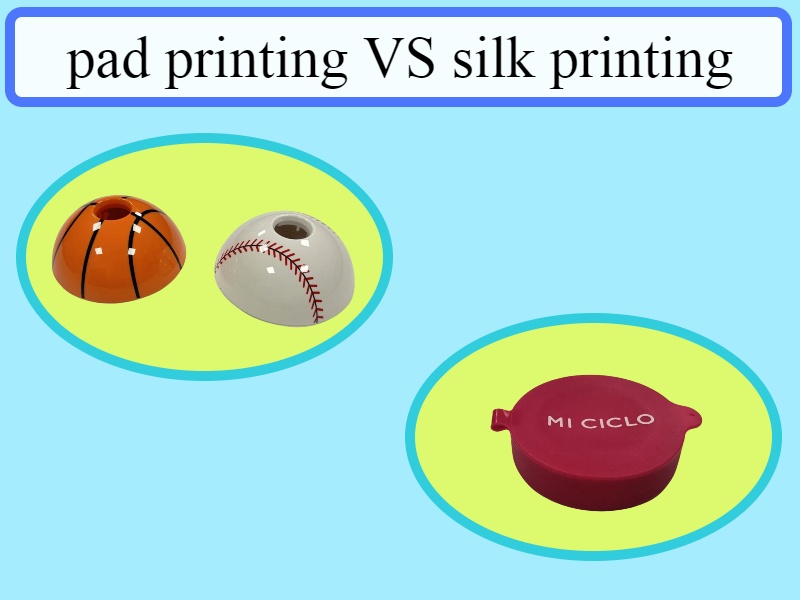

The different between mater engraving and pad printing

The specifications and information of current products have become an indispensable part. Most manufacturers will engrave the information on the products through silk scre...Read more -

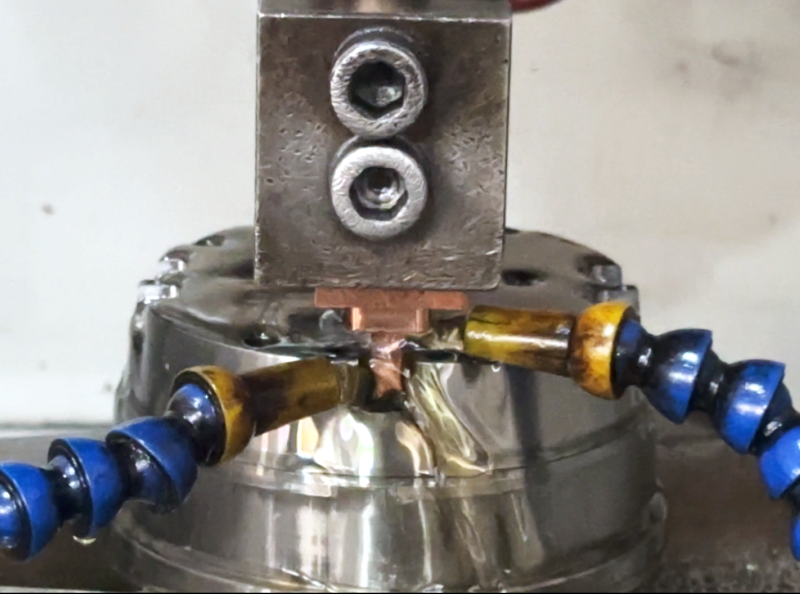

Electro spark treatment in mold processing

Today we discuss electro-spark deposition's apply in metal alloys , at the same time we will focus on this technology how to modify the mold in injection molding tooling a...Read more -

How to choose between injection molding and CNC machining

CNC and Injection as the two most be popular crafts for manufacture, which both can make the high-quality product or parts in each areas and they have their own advantages...Read more -

How To Make Health, Safety And clean Medical Device

When it comes to medical equipment, cleanliness, safety, is critical. All medical devices, whether disposable, implantable or reusable, must be cleaned during the manufact...Read more -

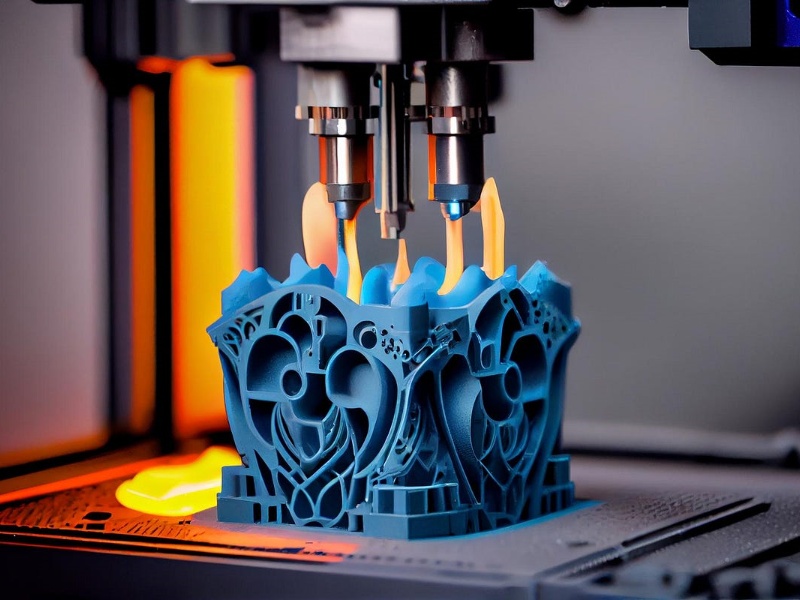

Types And Characteristics Of 3D Printing

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from digital models. Unlike traditional subtractive manufacturing m...Read more -

The Art Of Metal Engraving

Engraving, like sculpture, has a long and fascinating history that spans various cultures and time periods. Engraving is the practice of incising a design onto a hard, fla...Read more -

Understanding the Difference Between Pad Printing and Screen Printing

Pad printing and screen printing are two different printing methods that are used on a variety of products and on a variety of different materials. Screen printing is used...Read more -

Silk Print in Fashion and Home Decor productv

What is silk printing? Screen printing is pressing ink through a stencil screen to create a printed design. It is a broad technology that is widely used in different indus...Read more -

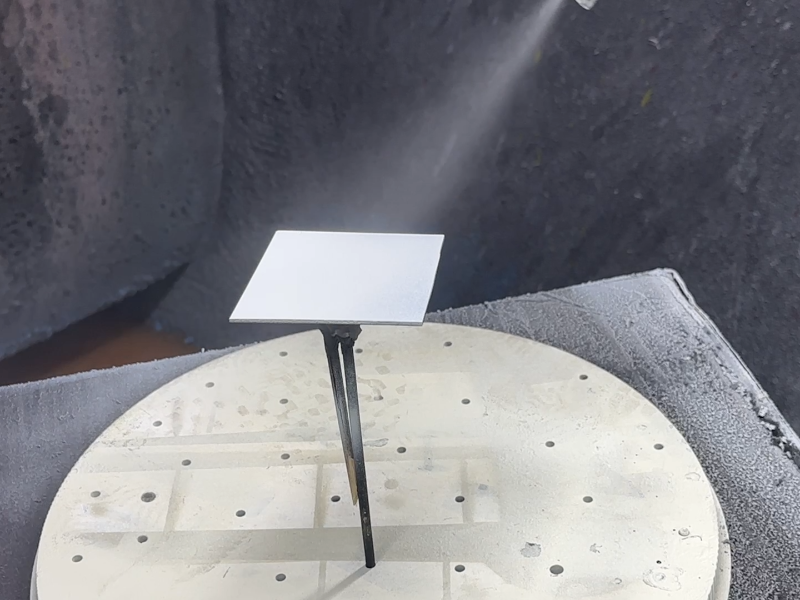

The Guide to injection mold Post-Processing Methods

Post-processing enhances the properties of plastic injection molded parts and prepares them for their intended end use. This step involves corrective measures to eliminate...Read more -

Exploring the Future of CNC Router Technology: Innovations and Trends to Watch

What is a CNC Router? CNC milling machines are automated machine tools that are widely used for cutting 2D and shallow 3D profiles from generally soft materials...Read more -

How Rubber Molding Technology Enhances Product Durability and Performance

Rubber molding is a manufacturing process that involves shaping rubber materials into specific forms and dimensions. This process is commonly used to produce a wide range ...Read more