Kajeno re buisana ka li-electro-spark deposition's apply in metal alloys , ka nako e ts'oanang re tla tsepamisa maikutlo ho thekenoloji ena mokhoa oa ho fetola hlobo ka lisebelisoa tsa ho etsa ente le liforomo tsa ho lahla.

Electro-Spark Deposition ke eng?

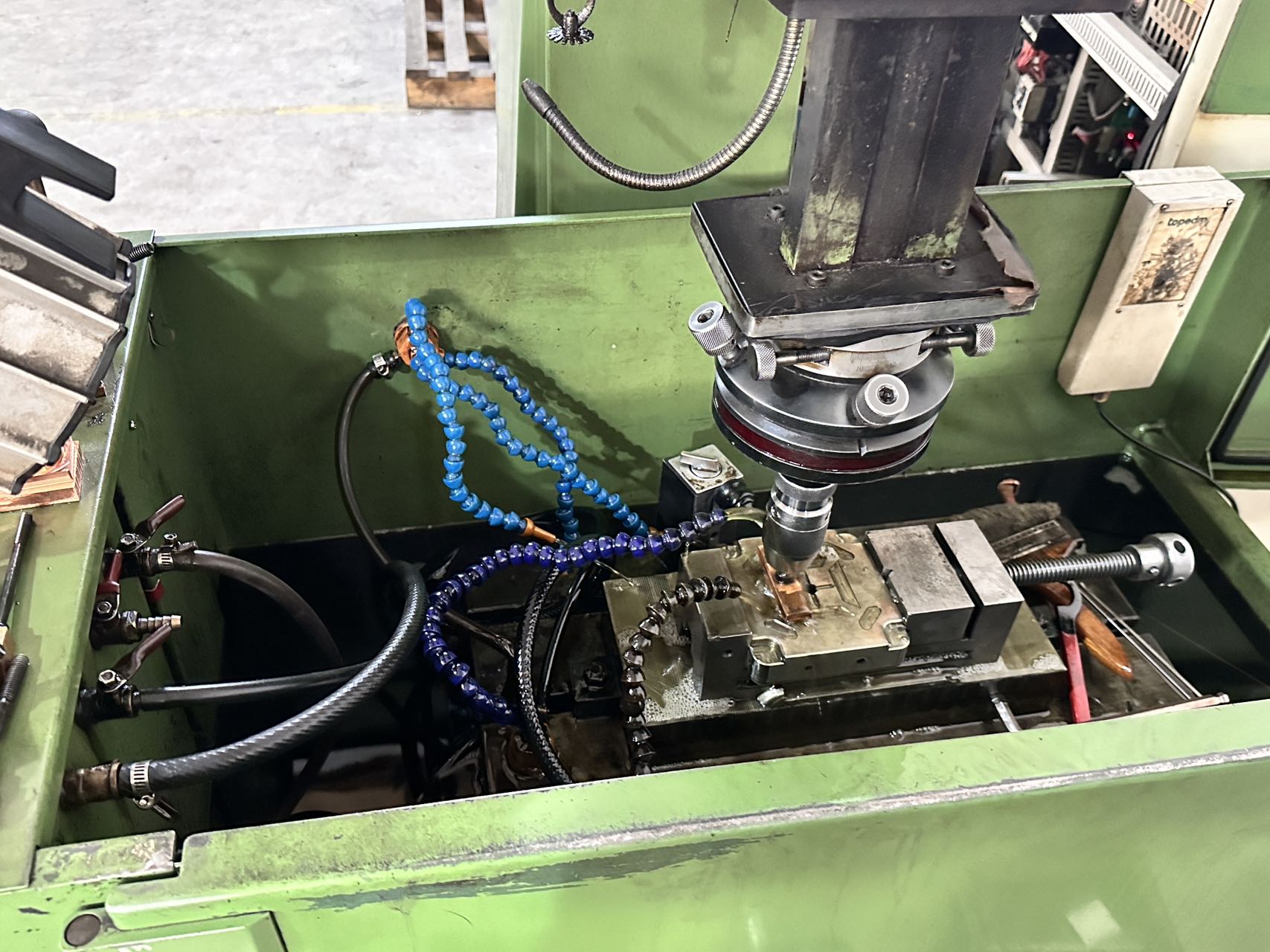

Electro-spark treatment, eo hape e tsejoang e le Electro-discharge machining (EDM), ke mokhoa o khethehileng oa tlhahiso o kenyelletsang tšebeliso ea lisebelisoa tsa motlakase ho theha le ho fetola bokaholimo ba likarolo tsa tšepe.

Nakong ea phekolo ea Electro-spark, ho tsoa motlakase ho hlahisoa pakeng tsa electrode le workpiece, hangata e entsoeng ka thepa ea conductive e kang tšepe kapa li-alloys.Ts'ebetso e qala ka ho beha electrode, hangata e le sesebelisoa se senyenyane, se bōpehileng, se haufi le mosebetsi.

Ha motlakase o sebelisoa pakeng tsa electrode le workpiece, letoto la ho tsoa ha motlakase ka potlako le etsahala.Melaetsa ena e baka mocheso o matla, o qhibilihisa likaroloana tse nyane tsa bokaholimo ba mosebetsi.Joale tšepe e qhibilihisitsoeng e tima ka potlako ke mokelikeli oa dielectric, e leng ho etsang hore e tiee ebe e etsa li-crater tse nyenyane kapa tse kenang.

ESD e sebelisoa ho metsoako ea tšepe

Ha matla a capacitor a lokolloa, motlakase o tobileng o etsa hore ho be le mocheso o phahameng oa mocheso oa plasma pakeng tsa ntlha ea electrode le tšepe ea alloy workpiece.Mocheso ona o phahameng oa mocheso o pakeng tsa 8000 le 25000°C.The plasma arc ionize anode 'me ka potlako e fetisetsa thepa e qhibilihisitsoeng ho workpiece.

Anode ena ea ionizing e fetisetsoa substrate ka li-pulses tse khutšoane.Arc e nang le mocheso o phahameng e na le likaroloana tsa anode, molapo oa mocheso (hot jet), le plasma e entsoeng ke ho bola ha likhase le liathomo tse sebetsang tsa naetrojene, oksijene le carbon.Boholo ba mocheso o tsamaisoa ke li-jets tsa mocheso le plasma.

Hobane li-pulse li le khutšoanyane, mocheso oa mocheso ka jete ea mocheso le likhase tse ling ha o fokotsehe, 'me mocheso o le mong feela oa mocheso ho substrate ke ka palo e nyenyane ea likaroloana tsa anode tse behiloeng holim'a substrate.Ka hona, li-pulse tsena li fetisetsa mocheso o monyenyane ho substrate ntle le ho fetola microstructure ea substrate.Mokhoa ona o molemo ho feta ts'ebetso ea fusion welding e atisang ho sebelisoa ho lokisa li-alloys tse nang le likarolo tse mpe tse amehang ke mocheso (mohlala, boima bo tlase, boima bo phahameng, ho phatloha ha liquefaction).

Ho feta moo, ts'ebetso e thusa ho theha maqhama a matla a metallurgical pakeng tsa substrate le ho roala.Microalloying pakeng tsa electrode melt le substrate qala sebopeho sa plasma ka ho bola ha moea, carbonates, carbides le nitrides.

Melemo

1.Ho nepahala le ho Nepaha: Kalafo ea Electro-spark e lumella hore ho be le sebōpeho se nepahetseng le se nepahetseng sa lintlha tse rarahaneng le li-contours tse rarahaneng holim'a tšepe.Lisebelisoa tsa motlakase tse laoloang li senya thepa ka mokhoa o laoloang, e leng ho nolofalletsang ho theha likarolo tse nepahetseng tse kang masoba a manyenyane, li-slots, kapa li-indent tse nang le ho nepahala ho phahameng.

2.Ho Sireletsa Botšepehi ba Lintho: E 'ngoe ea melemo ea bohlokoa ea phekolo ea Electro-spark ke bokhoni ba eona ba ho boloka boima le botšepehi ba mosebetsi.Ho fapana le mekhoa e tloaelehileng ea machining e ka hlahisang mocheso o feteletseng le ho etsa hore ho be le liphetoho tse sa batleheng ho thepa ea thepa, kalafo ea Electro-spark e fokotsa libaka tse anngoeng ke mocheso 'me e boloka ho thatafala ha mochini oa mosebetsi le sebopeho sa sebopeho.

3.Li-Geometri tse rarahaneng: Kalafo ea Electro-spark e nolofalletsa ho etsoa ha li-geometri tse rarahaneng tse ka 'nang tsa e-ba phephetso kapa tse ke keng tsa khoneha ho finyella ka mekhoa e tloaelehileng ea machining.Bokhoni ba eona ba ho bopa likarolo tse rarahaneng bo lumella ho hlahisa hlobo, ho shoa, kapa likarolo tse ling tse nang le li-contours tse ikhethang le lintlha tse rarahaneng, ho atolosa menyetla ea moralo.

4.No Tool Wear: Ho fapana le mekhoa e tloaelehileng ea machining e kenyelletsang ho itšeha kapa ho senya, phekolo ea Electro-spark ha e akarelletse ho kopana ka ho toba pakeng tsa sesebelisoa le workpiece.Ka lebaka leo, ho na le lisebelisoa tse fokolang tsa lisebelisoa, tse lebisang bophelong bo atolositsoeng ba lisebelisoa le ho fokotsa litšenyehelo tsa tlhokomelo.

Kakaretso

Sehlooho sena se kenyelletsa haholo-holo ts'ebetso ea EDM ka mokhoa oa ho etsa hlobo, eseng feela ho hlahisa mokhoa oa eona oa ho phalla, empa hape o hlahisa melemo e meholo ea ts'ebetso ena.Ka video e ka holimo, ke tšepa hore u ka utloisisa mokhoa ona ka ho hlaka.Haeba u na le lipotso tse ling, ka kopo ikutloe u lokolohile ho li arabaiteanye le rona.

Nako ea poso: Jun-07-2024